- Top

- About HARMO

- Global market

Global market

@2x.jpg?width=2732&height=940&name=2021%E5%90%8D%E5%8F%A4%E5%B1%8B%E5%B1%95(3)@2x.jpg)

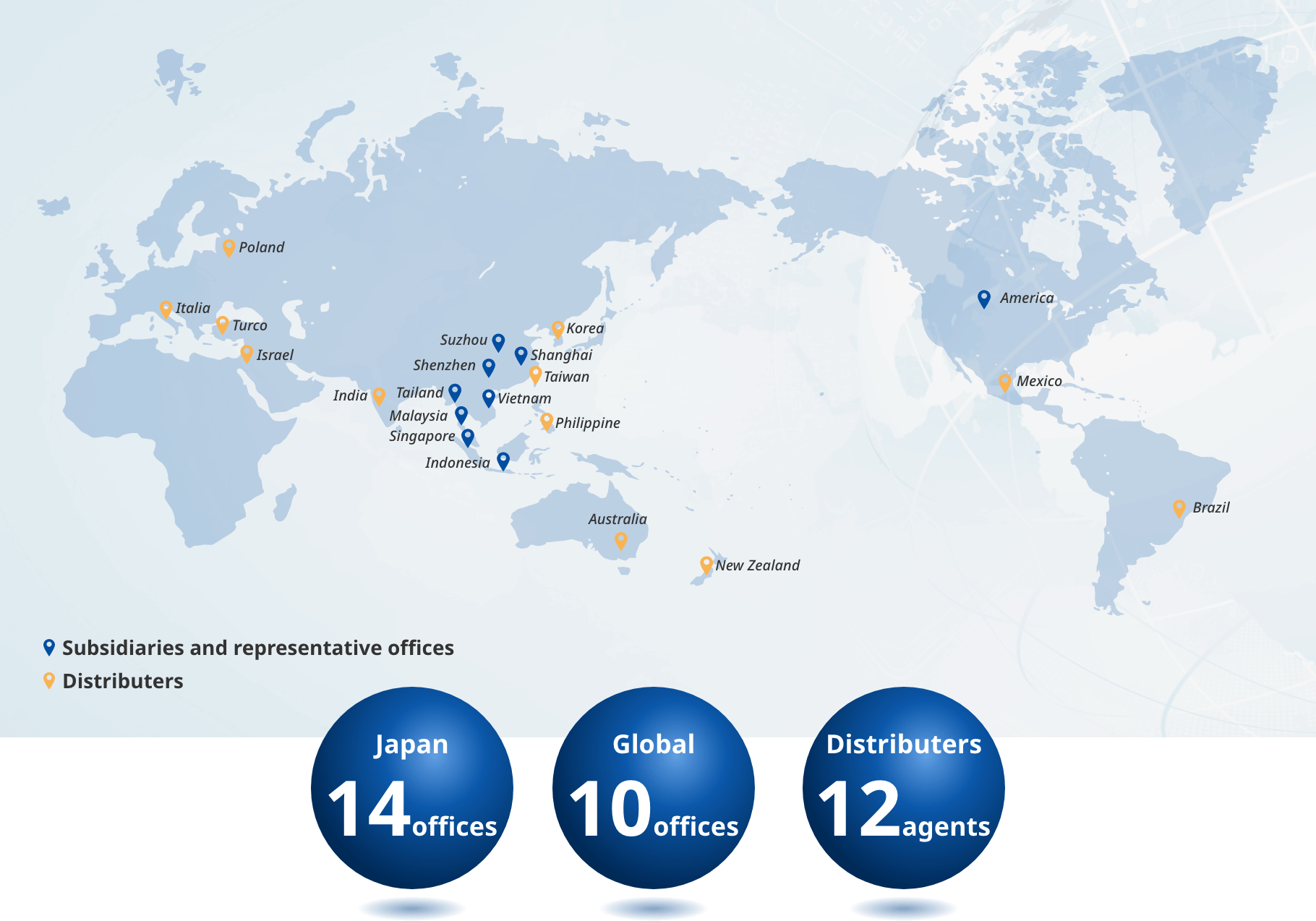

We are strengthening our global reach in order to assist our customers with the stable production of products around the world.

We can currently count on 10 overseas subsidiaries and representative offices, as well as on agents in 12 countries.

We currently support injection molding production sites primarily in Asia and America, but our aim is to further strengthen our global capabilities in order to expand our market share.

We sell products and provide services in several regions, primarily in Asia and the US. We have established sales and maintenance service networks in locations close to our customers to ensure that our products can be used correctly, efficiently and safely in any region.

Each office is staffed with local personnel with considerable experience and equipment knowledge. Rest assured and do not hesitate to contact them.

Problem-solving capabilities and service know-how cultivated in Japan

In the over 60 years since our establishment, we have dealt with all kinds of problems related to plastic injection molding.

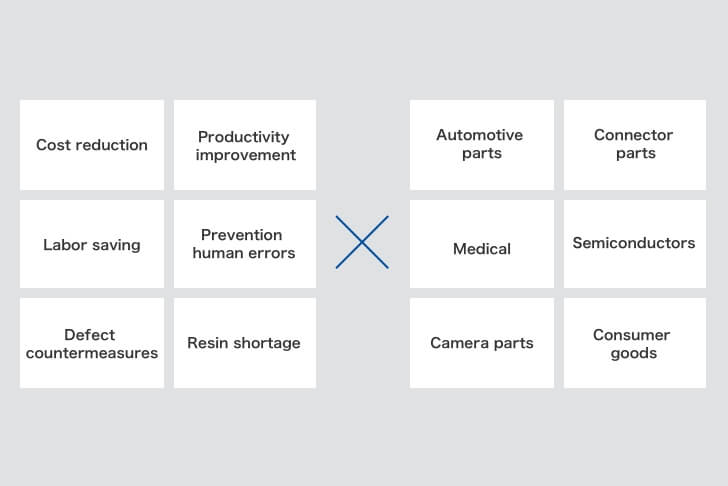

As a comprehensive manufacturer covering all aspects, from "molded parts take-out robots" to "automated peripheral devices," we propose optimized total solutions to cope with a wide range of customers’ issues, including automation and labor-saving operation of injection molding lines, productivity, defect countermeasures, quality consistency and more.

@2x.jpg?width=728&height=486&name=_A1D7732_SHIM%E3%80%90%E6%9C%AA%E5%87%A6%E7%90%86%E3%80%912000-sRGB%20(1)@2x.jpg)

Broad capabilities across countries, areas or industrial sectors

Customers’ injection molding problems widely vary depending on the country, area and type of business they are in.

While all regions are different (in some the production of automotive parts is thriving while others will focus on production of medical-related components), having helped the most diverse customers solve their problems, we are perfectly qualified to respond to sector-specific problems too.

MEMBERS VOICE

The Chinese market is becoming increasingly globalized

Ryuichi Jokura (International Sales Department)

Requirements of the Chinese market

In China, our primary customers are in the field of automotive-related products, but we also do business with manufacturers of electrical components like connectors, of consumer products like personal computers and mobile phones, as well as of medical products.

While China has traditionally been considered a source of cheap materials, the price of raw materials and chip components has risen considerably due to the Covid pandemic. Also, the historic drought of 2022 has seriously affected the generation of hydroelectric power, China's main power source, leading to power shortages. While deeply concerned about such a spike in costs, our customers have been very pleased with our gran cutters.

Gran cutters require expert craftsmanship in order to assemble the blades and must still be assembled in Japan. If it were possible to have the main parts sent over from Japan and then procure and assemble the rest locally, like we do with other products, prices would go down and our China sales figures would increase further.

While it’s the “Q” in QCD (Quality, Cost and Delivery) that allows us to recommend HARMO products with the utmost confidence, C and D are also taken into consideration. Having said that, HARMO’s strengths are speed, accuracy, and superior and easy-to-use features.

There are about 70 competing manufacturers, including Japanese companies and local manufacturers. HARMO was the last one on the scene, and we still have offices only in coastal areas, so we would like to increase the number of offices in the mainland in order to expand our sales activities.

Exhibitions are at the forefront of Chinese business

China used to have toy districts, mobile phones districts, cars districts and so on. However, as a result of the globalization of the market, industries are now concentrated in urban areas.

That’s true, in the past you would have 10 or 20 stores one next to the other, like in a wholesale district. While there are regional differences between areas like East/North China and South China, or South Shenzhen and Shanghai, these days there are a variety of industries wherever you go.

At present, exhibitions and shows can be said to be at the forefront of business in China. There are large and small ones in each region, and HARMO participates in "Chinaplas," Asia's largest trade fair for plastics and rubber, and in international exhibitions in Dongguan. In both cases, we mostly exhibit products from our Suzhou factory.

In the current Chinese market, once the Covid pandemic subsides, demand will definitely return to previous levels. They say that when the car-related sector takes off, all industries will follow, which is why we will continue to strengthen sales with automotive-related products as the main target, as we have done up to now.

Human resources in China

In order to set up new offices in the mainland too, it is necessary to develop local staff. The number of our employees is still small, and we must work at a large number of tasks with a small number of elite personnel.

While understanding and mutual communication between two cultures as different as those of China and Japan can sometimes be problematic, the whole process has also interesting aspects. We are currently seeking individuals who are interested in Chinese culture and who want to try and do their best in China.

Once a month Su holds a study session for local sales representatives on how to conduct proposal-based sales. I too am watching our local staff grow together. We have very high expectations for large countries like China and the United States, but Su lives up to those expectations every year and produces solid results.

I am very impressed.

Thank you very much.

As the person in charge of our local subsidiary, I will continue to do my very best.

.jpg)

MEMBERS VOICE

Developing new customers in growing markets

Ryuichi Jokura (International Sales Department)

Our local subsidiary in Thailand is the oldest one in Asia

Our company has seven offices (*) in Southeast Asia. Among them, our local subsidiary in Thailand was the first to be established. When I joined the company in 1991, Japanese staff were already stationed there.

*One office each in Singapore, Indonesia and Thailand and two offices each in Vietnam and Malaysia.

One of the reasons is that Injection molding has been popular in Asia for a long time, with production now expanding to the Philippines and China. As for Thailand, given the large number of Japanese companies operating there, a great deal of on-the-job communication is carried out in Japanese.

As for me, I’ve been stationed in Thailand from this year. Being stationed overseas is like having your own personal kingdom, and part of the charm is that that you can proceed with your work at your own discretion. I've heard that many Japanese companies send employees to Thailand as part of their training for overseas assignments, and I would say that so far everything has been to my liking (laughs).

Concerns of customers in growing markets

Thailand is home to many Japanese companies, especially automobile-related companies. Our company too does business with resin connector products for automobile-related components, as well as with camera-related manufacturers.

A large number of companies from countries other than Japan are also expanding into Thailand. There are many companies from China, South Korea and neighboring countries in Southeast Asia. And of course, local Thai companies are also active as injection molding manufacturers too. You can feel that it is a very vibrant area experiencing outstanding growth.

Improving productivity and quality are major themes in injection molding, but in Southeast Asia in particular, as a region where the market as a whole is growing, more and more customers are facing the issue of "increased labor costs" as a result of rising minimum wages.

Some automobile manufacturers are making a full-fledged shift to EVs (electric vehicles) and as a result of that the types of resins used in injection molding are also changing. If the type of resin changes, management methods will also change, affecting production yield (*). And quality control costs will also be affected.

*Yield: percentage of non-defective products out of all products produced in the manufacturing industry. A measure of productivity.

Aiming to “increase sales and customers”

HARMO's name recognition in Southeast Asia is still low. Until now, we have mostly conducted business with Japanese customers, but we believe that in the future it will be necessary to cultivate ties with local companies. In a market with such growth potential there are many unknowns. In this context, we feel that the connection between customers' problems and the value that our products can provide in response to them is not sufficiently attractive.

Yes, the road towards developing ties with local companies is still long. At our local Thai subsidiary we have an exhibition booth featuring our products. We invite customers to the company, where we hold private exhibitions and where they can see the actual machines, and we intend to take advantage of that even more.

With an eye to increasing contacts with local companies, I would like to increase the number of local staff too. I would like for them to feel the excitement of working in a growing area and the real thrill of pioneering a new market together.

MEMBERS VOICE

Communicating across distance and time differences

Shinichi Hirose (International Sales Office)

The necessity of interacting across distance and time differences

The area I’m in charge of is very wide, extending to Miami in the south, Montreal, in Canada, to the north and Colorado to the west, and sometimes it’s impossible for me to go to a customer even if they need after-sales service. In such cases, we ask them to send us photos and videos of the machine, and we use smart glasses (*) and zoom to assess conditions on the ground. We will then give them advise and arrange for parts, if necessary.

*Smart glasses are glasses-like wearable devices. By having HARMO’s staff and the customer wearing them, it is possible to share the other person's field of vision and assess the status of remote production sites and machines in real time.

Since smart glasses allow you to communicate visually and verbally, you can give verbal advice, transfer materials and communicate across remote areas. Various manufacturers in the United States are producing them, and I think they will eventually be used in Japan too.

Just as there is a time difference between the customer and Mr. Matsushita, there is a also time difference between me and Mr. Matsushita, with day and night being reversed and the date being different too. When it’s Tuesday night here, over there Monday’s work is about to start, so I need to keep that in mind when I have to contact him.

When communicating, we need to find a mutually convenient time. Mr. Matsushita has a family, so I try to adjust to his working hours as much as possible. That said, even if he goes home, since his home is close to the office, he can always come back to work after dinner. And when it’s difficult for him to do that, I will adjust my schedule to his situation, whether it’s daytime or the middle of the night.

In the morning, I will check emails and correspondence from Japan, and in the afternoon, I often respond to inquiries from the distributor’s sales representatives. When submitting reports, I try to send as many pictures and videos as possible to make it easier for the head office to understand the issues at hand. When we need technical advice to solve a problem, I share images and videos with the sales and engineering departments and get them to come up with ideas.

His reports arrive when I check my e-mail first thing in the morning, so I can start my day working on the American market. This too is an example of how well Mr. Matsushita is doing his job.

Digital marketing is essential

Regarding the differences between the US and Japan, Mr. Matsushita and I always have conflicting opinions, and he tells me that my head is still in Asia (laughs). It's not like in Japan, where you make a budget according to your investment plan, get an estimate, and check the actual products.

For example, if you click on what you want on Amazon, you will get it as early as the next day. So people buy our equipment expecting the same. If you can't move at that speed, you'll miss the opportunity to sell. We understand that and try to keep as much inventory as possible to meet customers’ needs. We are now creating a system for managing inventory items, so that Mr. Matsushita will not have to be the only one taking risks.

When it comes to small devices, we have customers who expect them to be shipped the next day. In Japan, delivery in a week or two is considered fast, but that's not the case here. Some people also watch HARMO's YouTube channel from Linkedin (*) and purchase through e-commerce sites.

We have data on how many people are redirected to the HARMO page from Linkedin, and the number is definitely increasing. Local companies are also helping us with digital marketing.

*LinkedIn: the world's largest business-specific social media. It is widely used, in the business world, especially overseas, as a way to collect information and connect with customers.

The way I see it, I can’t help but always be impressed by Mr. Matsushita's vitality and actions.